SMRC Resource Recovery Project

Waste Composting Facility Abatement

Project overview: how is carbon abated?

Alternative Waste Treatment

The Alternative Waste Treatment (AWT) method applies to projects that process mixed solid waste that would normally go to landfill, such as:

commercial and industrial waste

construction and demolition waste

municipal solid waste.

An AWT facility must be purpose built, either being a new facility or an expansion of an existing operation providing there are at least 24 months of historic data.

Eligible AWT technology operated at these purpose built locations include:

an anaerobic digester that collects the resulting biogas and sends it to a combustion device, such as a flare boiler.

Every tonne of waste diverted from landfill generates Australian Carbon Credit Units (ACCUs) as part of this method.

ACCUs are calculated as the difference between the baseline and project emissions:

the baseline is calculated on the amount of emissions that would have generated had the waste gone to landfill

project emissions are produced by composting or anaerobic digestion.

Project history

This project transitioned from a revoked Carbon Farming Initiative method and continues to divert mixed solid waste from landfills to the waste treatment facility for processing using an enclosed composting technology.

The project has generated in excess of 150,000 ACCUs for emission reduction activities to date.

For more information see Project ID: EOP100194.

An integrated strategy

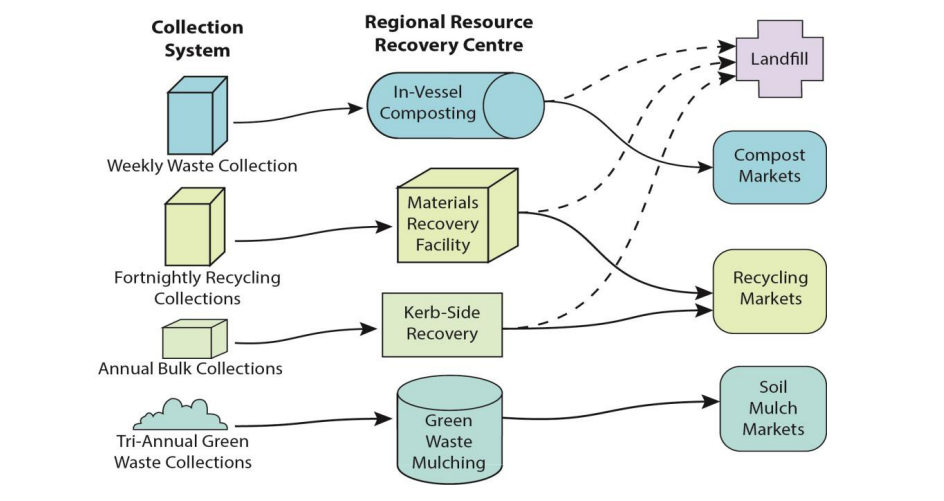

The SMRC has effectively harnessed its regional resources to develop a flexible and integrated strategy for sustainable waste resource recovery from the domestic waste stream.

The system has been successful in combining community behaviour with advanced processing technology and end-product marketing as a holistic package.

Illustrated on the image above.

Southern Metropolitan Regional Council

The Southern Metropolitan Regional Council (SMRC) is a statutory local government authority established in 1991 by local governments in the southern part of metropolitan Perth.

The SMRC region encompasses 340 square kilometres within Perth’s southern metropolitan area, and has a combined population of over 288,000 people. For the period of ACCU claim, waste tonnes from the following councils are accounted for:

City of Cockburn

Town of East Fremantle

City of Fremantle

City of Kwinana

City of Melville.

The SMRC is responsible for delivering innovative and sustainable waste management solutions for the benefit of its communities and the environment. The SMRC operates the Regional Resource Recovery Centre (RRRC) in Canning Vale, which receives, recycles, and processes waste from some of its member local governments and the community.

Project Update

Until July 2019, the SMRC domestic waste regional management strategy involved weekly collections of mixed municipal solid waste (MSW) processed through the in-vessel system at the Waste Composting Facility (WCF).

From July 2019 onwards, as part of Strategic Community Plan 2016-2026, the SMRC and its local government member councils progressively implemented a source separated Food Organics and Garden Organics (FOGO) collection system.

This project page currently reflects AWT operations and ACCUs generated to date.

The change to Source Separated Organic Waste will be reflected later.

Regional Resource Recovery Centre

The RRRC is an advanced waste processing facility that has been constructed on a 12-hectare site in Bannister Road, Canning Vale. It is centrally located to service the SMRC’s member councils. Each of the member councils have underwritten the development of the RRRC and adopted a uniform collection system to ensure the facility receives a consistent quantity and quality of domestic waste for processing.

This minimum service level outlined above is provided by all member councils. Modelled on proven waste processing technology the RRRC has been specifically adapted to suit Western Australia’s unique physical, economic and social conditions. It comprises separate facilities for organic waste processing, green waste mulching and sorting and recovery of recyclable materials.

The RRRC maintains an Environmental Management System (EMS) that meets with ISO 14001:2004 Standard requirements. The RRRC’s EMS ISO 14001 certification has been maintained since the 5th August 2010 with the initial annual compliance audit completed in June 2011, and continued certification being granted by independent verification each year.

The Material Recovery Facility (MRF): uses systems and equipment to recover recyclables from the domestic recycling MGBs coloured olive green with a yellow top. All plastics, glass, paper, cardboard, aluminium and steel products are separated and baled at the MRF. The processed material is sold into Australian and international reprocessing markets for manufacture of new products.

Greenwaste Facility: A separate facility, operational since November 2001, processes clean green waste from bulk kerbside collections. All of the material collected is ground into mulch for supply to organics markets.

Waste Composting Facility: The WCF consists of an advanced aerobic integrated composting facility that diverts waste from landfill. Approximately 60% of the waste is recovered as a resource for re-use and production of compost. The residual waste stream consists of processed inert material and is disposed to landfill.

Project operations and outcomes

Source separation approach

As part of its new Strategic Waste Management Plan (SWMP) developed in 2016, the SMRC and its local government member councils have decided to implement a source-separated Food Organics and Garden Organics (FOGO) collection system.

The new collection and processing system have been selected as the most suitable approach to achieve the objectives of the participating member councils. The aim is:

To implement a three bin FOGO collection and composting system, with the management framework and methodology to be adopted across the southern metropolitan region.

The FOGO collection system replaces the existing 240L MGB for general waste , with a 140L red lid general waste bin plus a lime lid 240L FOGO bin.

The 240 L commingled recycling (yellow lid) bin remains the same. The new configuration is funded under the Waste Authority’s Better Bins Programme.

The new collection system includes:

a weekly collection of 240L FOGO bin (new lime green lid bin)

fortnightly collection of 240L recycling bin (existing yellow lid bin)

fortnightly collection of a 140L general waste bin (new red lid bin).

Trial prior to rollout

One of the key actions was to conduct a trial FOGO system within the region and in December 2016 a FOGO project steering group was formed by the SMRC with representation from the Cities of Melville, Fremantle and Kwinana and the Town of East Fremantle.

After examining the demographics of the SMRC region, five representative areas were chosen within the City of Melville to be part of the FOGO trial totalling approximately 7,000 households starting in October 2017.

The rollout of FOGO within City of Fremantle, Town of East Fremantle and City of Melville is occurred for the period 1 July 2019 to 18 October 2019. Implementing this system aligns with the WA Waste Strategy 2030 in diverting waste from landfill and meeting the objective of “no more than 15% of waste generated in Perth and Peel regions is landfilled” by 2030.

Note that from discussion with the Clean Energy Regulator and under the AWT Methodology, FOGO collected at source from a three bin system does not meet the criteria for “eligible waste”, and has not been accounted for as part of an ACCU claim purposes.

Waste compost facility

The SMRC’s WCF, located at the RRRC, is an aerobic integrated composting facility that diverts waste from landfill. Prior to the construction of the WCF, waste was disposed of in three landfill facilities located in the metropolitan areas of Canning, Cockburn and Rockingham.

In the absence of the WCF, the waste disposed of to landfill facilities would contain a high proportion of organics (60% by volume) and greenhouse gas (GHG) emissions as methane would be generated.

The aerobic composting technology utilised at the WCF is a carbon neutral process enabling a large fraction of the organic carbon within the waste stream to be converted to compost.

The compost can, when applied regularly to the soil, increase soil organic content, which can result in a decrease in atmospheric carbon through sequestering carbon.

The SMRC has taken a conservative approach to the measurement of GHG abatement by not taking into account the potential net sequestration function in the Project abatement calculations.

The construction of the WCF was completed in December 2003 and the facility was commissioned in February 2004.

Between December 2015 and June 2020:

246,939 tonnes of municipal solid waste has been diverted from landfill and processed at the WCF.

In this financial years reporting period (July 2019 to June 20), 14,356 tonnes of eligible waste was processed.

Future Waste Processes

Due to the shift from an AWT methodology to a FOGO system the project team are in conversation about how this procedural transition will be operated as part of the CSF.

Conversations about the CSF scheme with the Clean Energy Regulator (CER), a Government body responsible for accelerating carbon abatement for Australia through the administration of the National Greenhouse and Energy Reporting scheme, Renewable Energy Target and Climate Solutions Fund, are regularly provided by project participants.

In this manner complicated processes such as a transition of method, undertaken to improve system outcomes, are often resolved for the benefit of program operations.

Eligible waste

The SMRC has implemented a regional waste strategy to divert waste from landfill. The general waste accepted at the WCF is putrescible in nature and comprises MSW and commercial and industrial waste (C&I).

Inert waste is not accepted at the WCF.

The waste for the ACCUs generated to date is processed and composted using an aerobic in-vessel waste treatment technology at the WCF.

The implementation of FOGO operations adjusts the need for the aerobic in-vessel technology.

Waste compost facility process flow for the AWT method

Municipal solid waste is source separated into general waste and commingled recycling using a two stream mobile garbage bin system.

Recyclable materials are transported to the SMRC MRF and general waste is processed at the WCF.

Bulky non-biodegradable items and hazardous material are separated from the MSW stream.

Note: the SMRC member councils conduct kerbside green waste pickups between two to four times a year to reduce the amount of hazardous and bulky non-biodegradable material in the general MSW stream.

The remaining waste from the verge-side pick ups is batch-fed into the first compartment of the three-compartment rotary digester (known as an Eweson Digester).

Recirculated process leachate is fed into this compartment.

An aerobic digestion process takes place in the digester as it rotates and temperatures are maintained at an average of 50°C.

The waste is batch-transferred between compartments each day for 3 days.

The resulting material is prepared for the secondary composting stage.

The organic components of the processed waste stream have been microbially converted to immature mixed waste organic output.

Inorganic materials constitute around one third by weight of the output from the digestion process and remain intact and are separated by a trommel screen and taken to landfill.

The bulk of this residual waste is plastic.

The mixed waste organic output is then transferred to the aeration floor building for stabilisation for 28 days. It then passes through a fine screen.

All air from the digesters and the enclosed receiving warehouse and aeration building is extracted and passed through biofilters comprised of woodchips to mitigate odour emissions.

Waste compost facility process flow for the FOGO process

Municipal solid waste is collected from households in a 240 L MGB and processed at the WCF.

The SMRC member councils conduct kerbside green waste pickups between two to four times a year to reduce the amount of hazardous and bulky non-biodegradable material in the general MSW stream.

Bulky non-biodegradable items and hazardous material are separated from the MSW stream.

The remaining waste from the verge-side pickups is batch-fed into the first compartment of the three-compartment rotary digester (known as a Eweson Digester). Recirculated process leachate is fed into this compartment.

An aerobic digestion process takes place in the digester as it rotates and temperatures are maintained at an average of 50°C. The waste is batch-transferred between compartments each day for 3 days. The resulting material is prepared for the secondary composting stage.

The organic components of the processed waste stream have been microbially converted to immature mixed waste organic output (MWOO).

Inorganic materials constitute around one third by weight of the output from the digestion process and remain intact and are separated by a trommel screen and taken to landfill. The bulk of this residual waste is plastic.

The MWOO is then transferred to the aeration floor building for stabilisation for 28 days. It then passes through a fine screen to generate the final compost product.

All air from the digesters and the enclosed receiving warehouse and aeration building is extracted and passed through bio filters comprised of woodchips to mitigate odour emissions.

Co-benefits: compost for communities and farms

The SMRC Resource Recovery project generates compost quickly and efficiently while abating carbon dioxide-equivalent emissions.

The resource that is generated from household waste adds nutrients to soils in the surrounding region.

Instead of landfill waste, this process creates a high quality resource.

Co-benefits: job creation

Waste, Jobs and Resources

Recycling creates approximately 7 times more jobs than landfill. An increased focus on managing resources has a tangible effect on economic livelihoods.

‘With the outcomes and co-benefits available to a range of stakeholders, it makes sense to maximise the value of organic discards. Allowing waste to rot in landfill truly does not make sense when it can be utilised as a resource that benefits the land we gain food from, the air we breathe and the livelihoods of a number of people.’

Project overview: United Nations Sustainable Development Goals (UN SDGs)

Zero hunger

Processed waste from the AWT facility is provided to farmlands in the nearby region. This resourceful process enables a circular economy process where the waste from organic material is processed to become a resource, nutrient enriched compost, that is utilised to grow crops to be eaten by the consumers who sent the waste to the facility.

The activities align with the following UN SDG targets and indicators:

Target

2.4: By 2030, ensure sustainable food production systems and implement resilient agricultural practices that increase productivity and production, that help maintain ecosystems, that strengthen capacity for adaptation to climate change, extreme weather, drought, flooding and other disasters and that progressively improve land and soil quality

Indicators

2.4.1: Proportion of agricultural area under productive and sustainable agriculture.

Quality education

The RRRC Education Centre is an important educational resource for surrounding schools, the regional community and other visitors. It features a number of interactive models and learning experiences.

The RRRC offers free tours which are designed to educate visitors about the recycling process and allow safe and exciting views from observation decks into the various facilities.

The activities align with the following UN SDG targets and indicators:

Target

4.3: By 2030, ensure equal access for all women and men to affordable and quality technical, vocational and tertiary education, including university

Indicators

8.2.1: Participation rate of youth and adults in formal and non-formal education and training in the previous 12 months, by sex.

Clean water and sanitation

Reducing waste going to landfill dramatically negtates the chance that harmful refuse ends in water sources. In addition, the FOGO operations and the focus on improving how the community manages waste that they need to send to landfill allows for hazardous waste to be managed effectively.

All of these reasons assist in the prevention of nearby water sources becoming contaminated by pollutants.

The activities align with the following UN SDG targets and indicators:

Target

6.3: By 2030, improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials, halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally.

Indicators

6.3.2: Proportion of bodies of water with good ambient water quality.

Decent work and economic growth

The creation of the facility and improvement of resource recovery processes is driving economic growth for the community. Notably, as an overall evaluation of the landfill to resource recovery job opportunity:

The activities align with the following UN SDG targets and indicators:

Target

8.2: Achieve higher levels of economic productivity through diversification, technological upgrading and innovation, including through a focus on high-value added and labour-intensive sectors.

Indicators

8.2.1: Annual growth rate of real GDP per employed person.

Target

8.4: Improve progressively, through 2030, global resource efficiency in consumption and production and endeavour to decouple economic growth from environmental degradation, in accordance with the 10-year framework of programmes on sustainable consumption and production, with developed countries taking the lead.

Indicators

8.4.1: Material footprint, material footprint per capita, and material footprint per GDP

Industry, innovation and infrastructure

Similarly to SDG8, above, the RRRC is achieving SDG targets that create opportunity for the waste industry and the community.

Improvements in innovation of composting facilities is enabling less waste and more resource to be generated from operations.

The activities align with the following UN SDG targets and indicators:

Target

9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities.

Indicators

8.2.1: CO2 emission per unit of value added.

Sustainable cities and communities

Similarly to SDG8, above, the RRRC is achieving SDG targets that create opportunity for the waste industry and the community.

Improvements in innovation of composting facilities is enabling less waste and more resource to be generated from operations.

The activities align with the following UN SDG targets and indicators:

Target

11.6: By 2030, reduce the adverse per capita environmental impact of cities, including by paying special attention to air quality and municipal and other waste management.

Indicators

11.6.1: Proportion of urban solid waste regularly collected and with adequate final discharge out of total urban solid waste generated, by cities.

Responsible consumption and production

Improving waste recovery and resource efficiency procedures throughout the communities that SMRC operates is aiding in reducing refuse ending in landfill or other areas of the environment.

Additionally, the implementation of easy to use systems and education to highlight how the community can assist in the process encourages citizens to be active consumers along the supply chain.

The activities align with the following UN SDG targets and indicators:

Target

12.3: By 2030, halve per capita global food waste at the retail and consumer levels and reduce food losses along production and supply chains, including post-harvest losses.

Indicators

12.3.1: Global food loss index.

Target

12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.

Indicators

12.5.1: National recycling rate, tons of material recycled.

Climate action

The reduction of GHG emissions from landfill waste is a core component of operations in collection of waste and at the facility. Further down the supply chain the addition of nutrient rich compost to soils in the region improves the natural environments ability to sequester carbon dioxide-equivalent in soils and plants.

The activities align with the following UN SDG targets and indicators:

Target

13.2: Integrate climate change measures into national policies, strategies and planning.

Indicators

13.2.1: Number of countries that have communicated the establishment or operationalization of an integrated policy/strategy/plan which increases their ability to adapt to the adverse impacts of climate change, and foster climate resilience and low greenhouse gas emissions development in a manner that does not threaten food production (including a national adaptation plan, nationally determined contribution, national communication, biennial update report or other).

Life below water

Similarly to SDG 6 the reduction of debris waste in landfill and improved management of post-consumer resources enables the facility to be part of the reduction of pollutants entering marine environments.

The activities align with the following UN SDG targets and indicators:

Target

14.1: By 2025, prevent and significantly reduce marine pollution of all kinds, in particular from land-based activities, including marine debris and nutrient pollution.

Indicators

14.1.1: Index of coastal eutrophication and floating plastic debris density.

Life on land

Utilising nutrient rich compost as a key resource on farm and community land the project is able to be part of a solution to protect land in the nearby region. In addition less waste is ending in landfill, relieving that land area from an associated stress.

The activities align with the following UN SDG targets and indicators:

Target

15.3: By 2030, combat desertification, restore degraded land and soil, including land affected by desertification, drought and floods, and strive to achieve a land degradation-neutral world.

Indicators

13.2.1: Proportion of land that is degraded over total land area.

Sources of demand for ACCUs

There are multiple possible sources of demand for the Australian carbon credit units (ACCUs) generated by Emissions Reduction Fund projects, including:

Voluntary markets

State and territory governments.

For more information about the sources of demand for ACCUs, see the Clean Energy Regulator’s presentation “Sourcing ACCUs in the market”.

Emissions Reduction Fund auctions

Emissions Reduction Fund participants with a registered project may bid for a contract to sell their Australian carbon credit units to the Clean Energy Regulator. The Clean Energy Regulator will run auctions to select bidders according to price.

Contract holders may also purchase ACCUs from un-contracted projects to meet contractual obligations.

Safeguard mechanism

Under the safeguard mechanism, particular facilities are required to keep their emissions at or below a baseline set by the Clean Energy Regulator.

Safeguard facilities who exceed their emissions baseline are able to surrender ACCUs to offset excess emissions.

Both Kyoto and non-Kyoto ACCUs can be used as credits under the safeguard mechanism.

Read more about the safeguard mechanism.

Other markets

Organisations may wish to voluntarily offset their emissions for meeting certification under the Climate Active Carbon Neutral Certification Standard (formerly the National Carbon Offset Standard).

State and territory governments are also seeking to be carbon neutral and may source ACCUs to offset their emissions.

Purchasing ACCUs from SMRC Resource Recovery project

Corporate Carbon Advisory have the rights to sell/retire ACCUs for this project. This includes the right to bid for an auction contract and to sell it as a credit on the voluntary market to assist organisations in meeting certification under Climate Active, or similar, standards.

Contact the team to learn about current availability of SMRC Resource Recovery ACCUs.

Visiting the RRRC

A unique opportunity to learn more about the project is offered at the RRRC.

Organisations and/ or individuals who would like to visit the facility and learn about the range of activities that assist in carbon abatement & sequestration and the co-benefits in the region, can have a first hand experience.

The RRRC Education Centre is an important educational resource for surrounding schools, the regional community and other visitors.

It features a number of interactive models and learning experiences.

The RRRC offers tours which are designed to educate visitors about the recycling process and allow safe and exciting views from observation decks into the various facilities.

Additionally SMRC offers a virtual tour of the Green Waste and Materials Recovery Facilities.

Contact the team to learn more about this unique package.

All photographs and content have been approved for use on this webpage.